Even in factories with overpressure ventilation to protect against contamination, roller cutters are still ground on the slitter. This produces grinding dust which contains cobalt and tungsten carbide and can contaminate the slitter / blank / can.

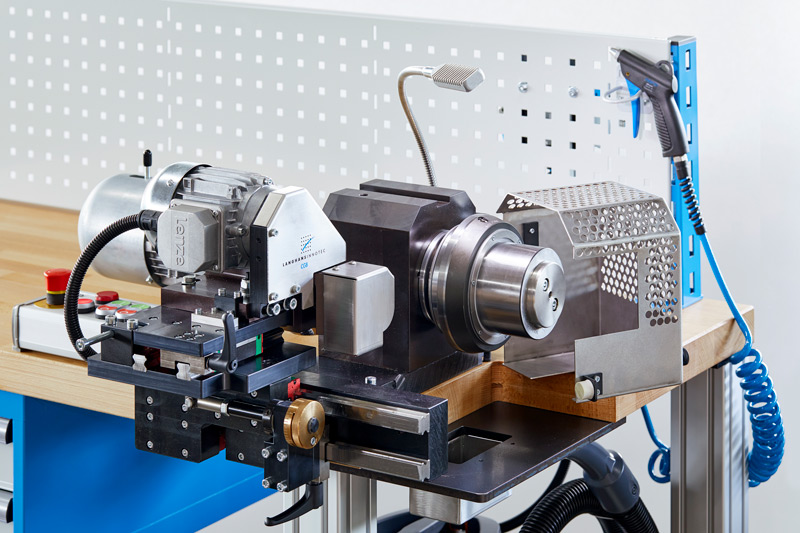

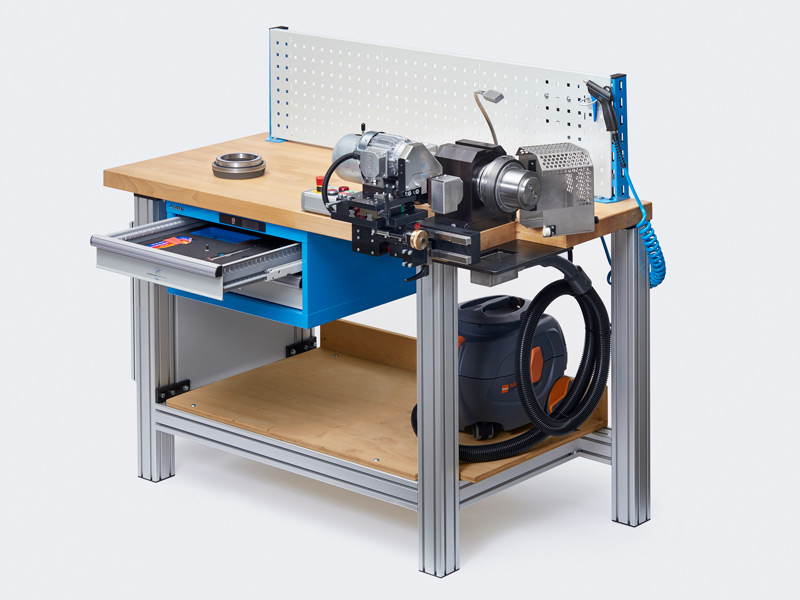

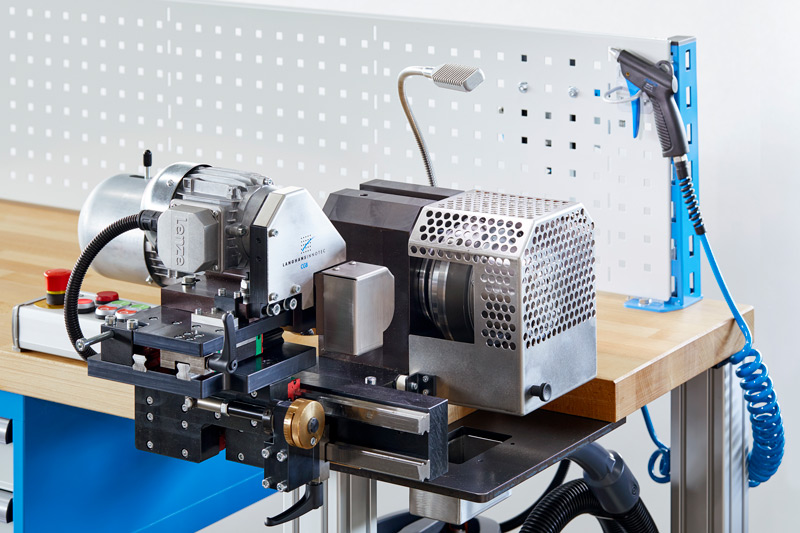

„Off-line” grinding offers further advantages over conventional grinding in addition to zero contamination. For example a higher line efficiency, maximum operator safety, optimized grinding quality by regrinding without production pressure and a longer service life of the roller cutters as no contamination by carbide grinding dust occurs.

With an optional safety package including risk analysis, the Roller Cutter Grinding Table also meets the highest safety requirements.

Hygienic off-line grinding with the CGB is essential, especially in the production of cans for food, in order to meet the requirements of FSSC 2200 or the HACCP system!