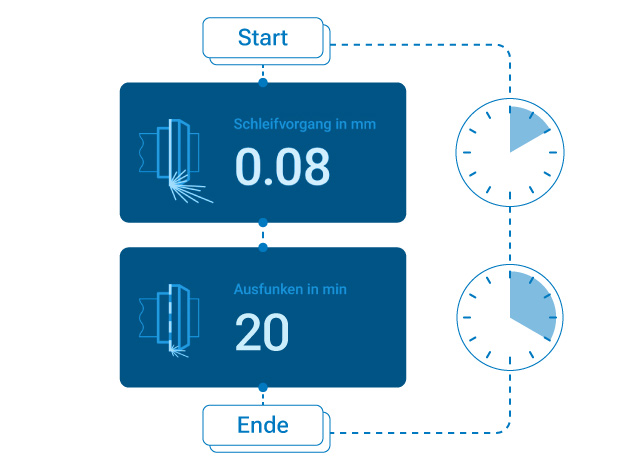

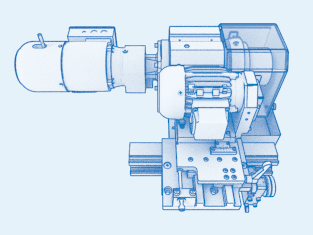

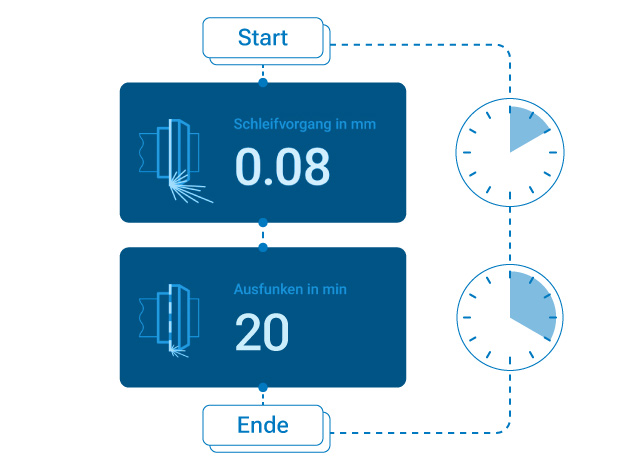

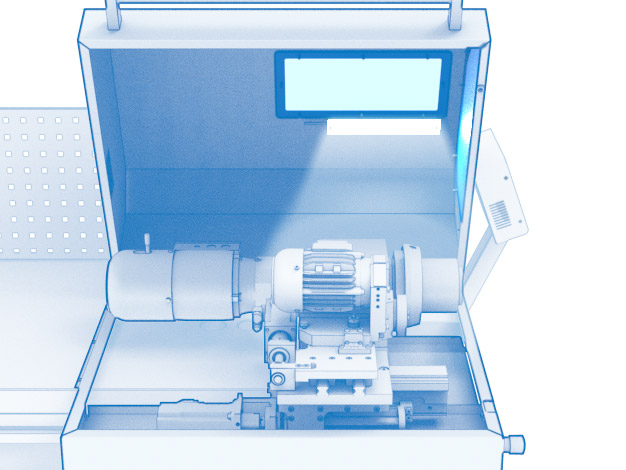

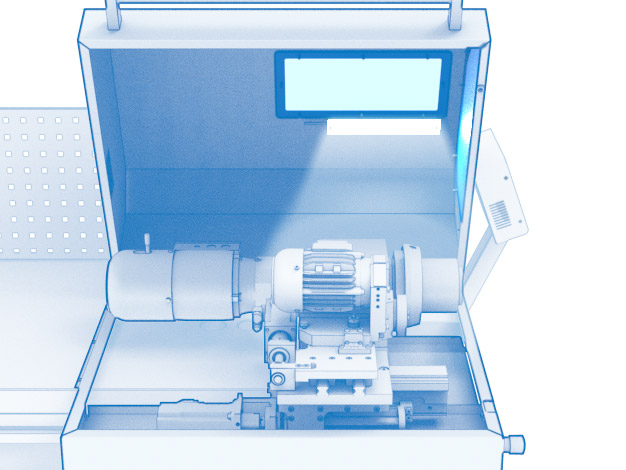

Automatic grinding, no operator required during the grinding process

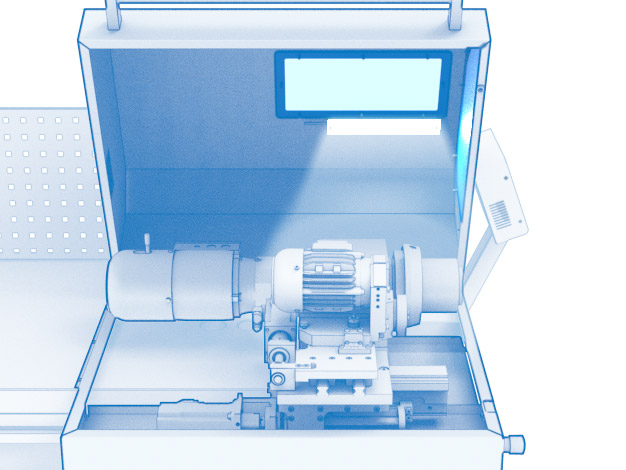

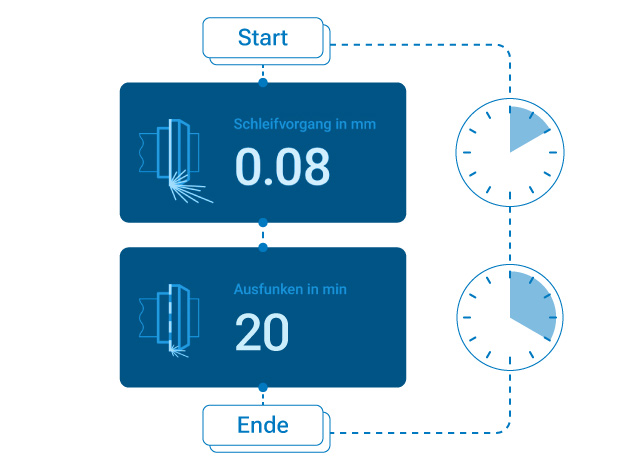

Operation & information on the status of the grinding process on the touch panel

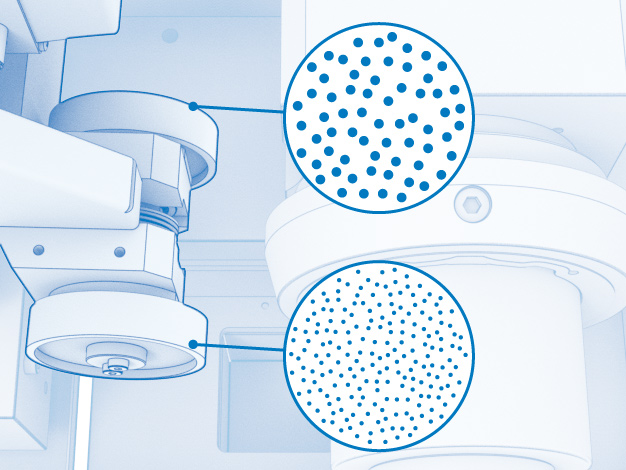

Selectable grinding process; repair or resharpening

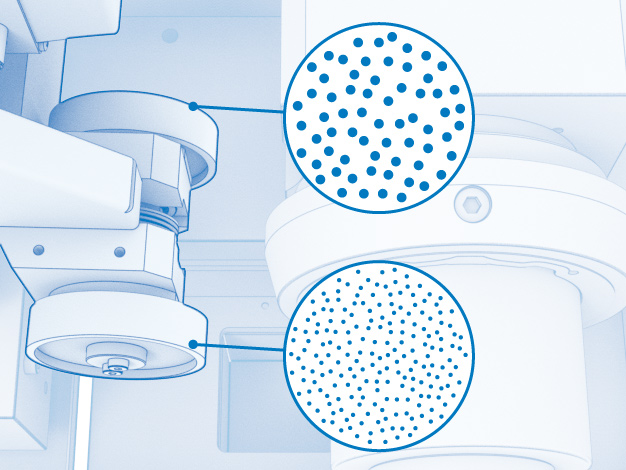

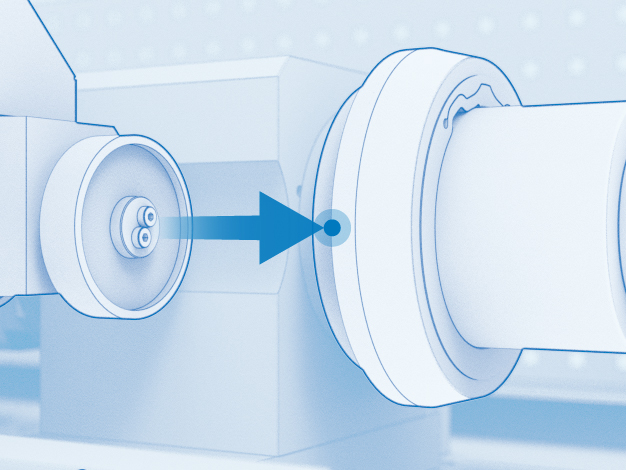

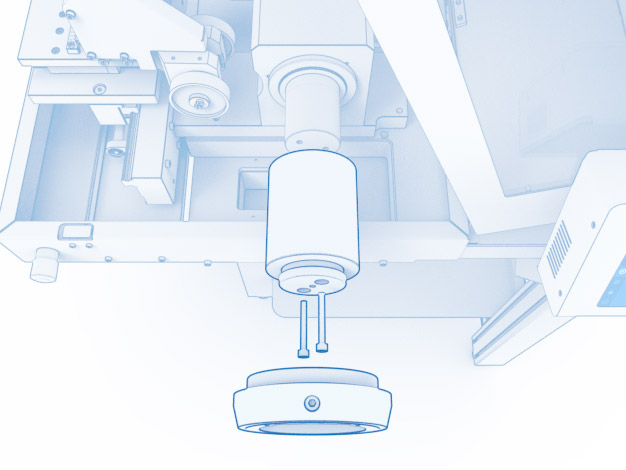

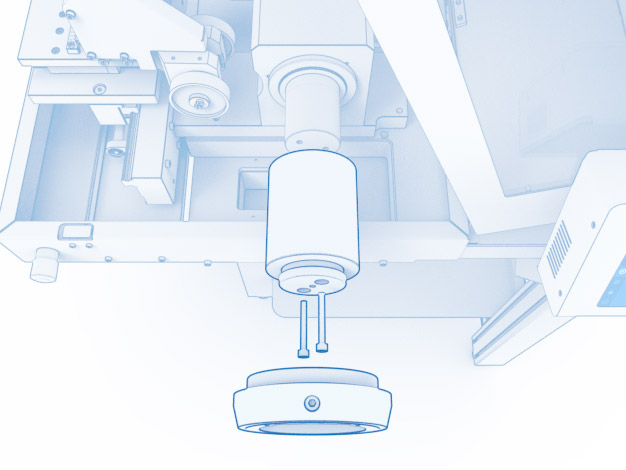

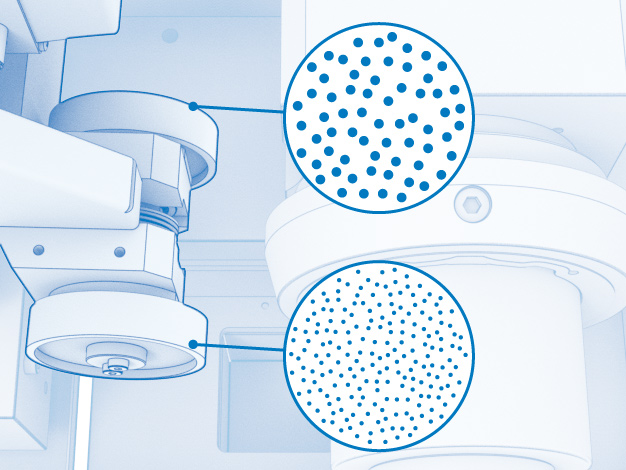

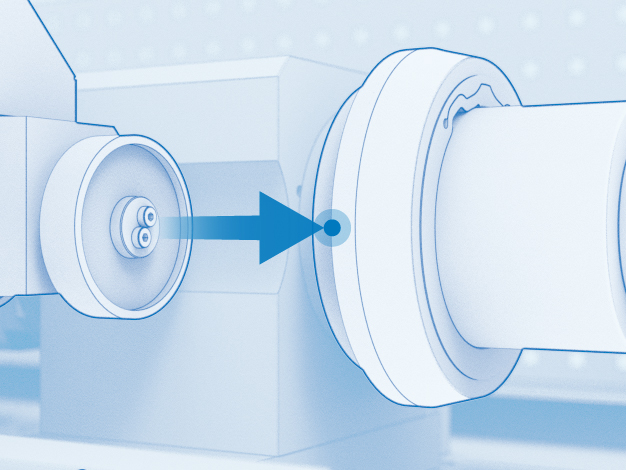

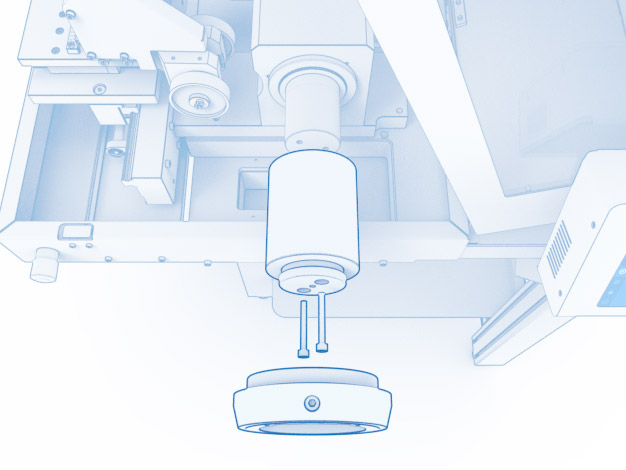

Automatic probing of the cutting edge to be sharpened

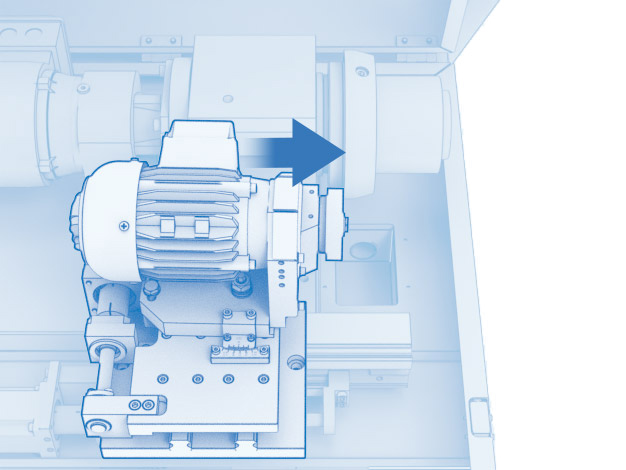

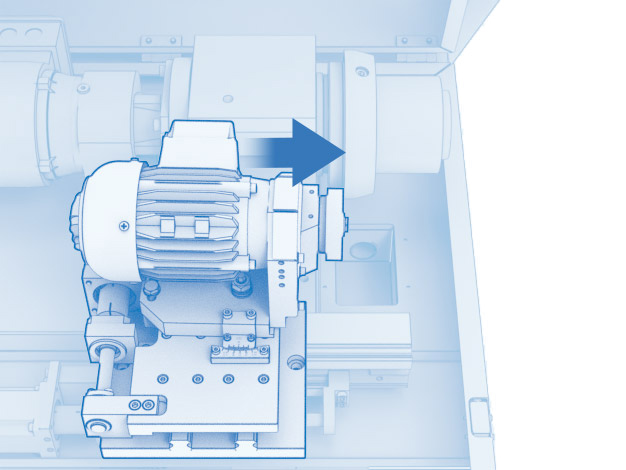

Continuous infeed of the grinding disc, 0.01 mm/min.

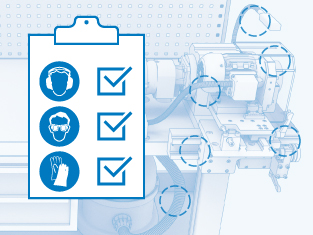

Safety cover with integrated LED work light

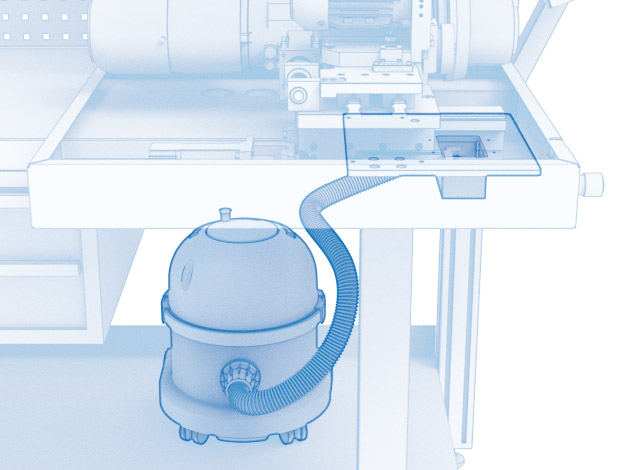

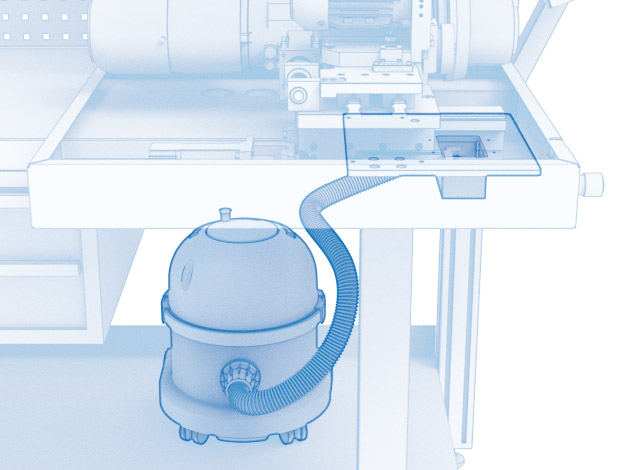

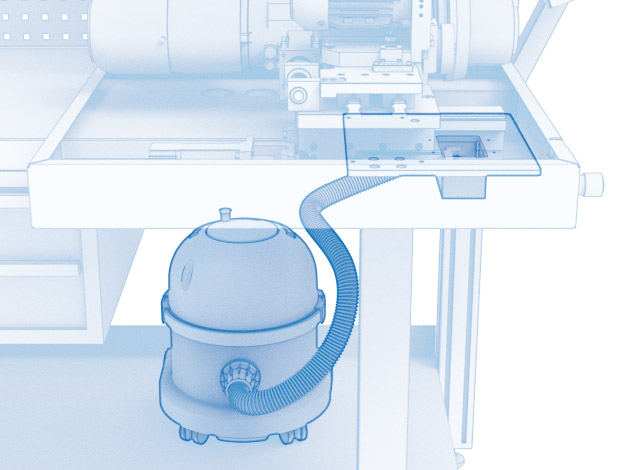

Integrated grind dust extraction

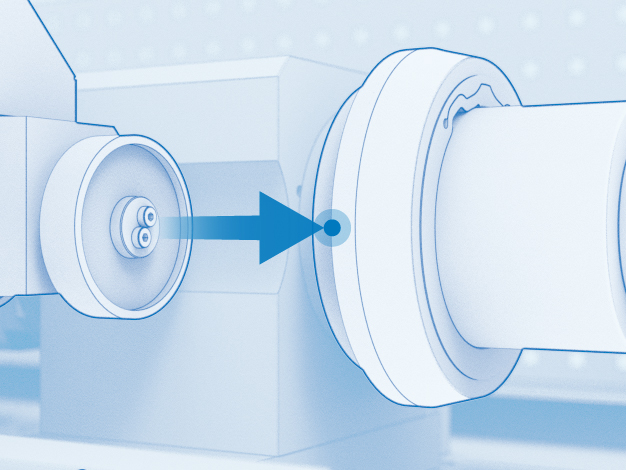

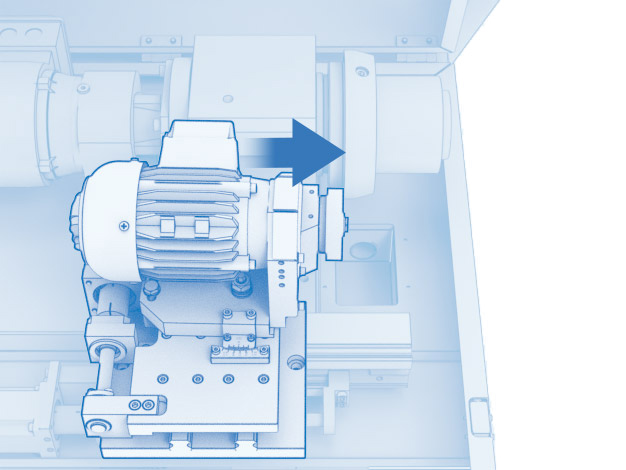

Replaceable cutter shaft for regrinding of different roller cutters